Workshop, Pump & Electrical Motor Repairs

WORKSHOP, PUMP & ELECTRICAL MOTOR REPAIRS

Workshop Refurbishments

Our workshop facility offers in-house assessments and maintenance/repair services of electro-mechanical parts/components:

Pumps

Electrical motors

Gearboxes

Fans and compressors

The repair services are undertaken with our machines/equipment that were designed and built in-house to ensure that they are fit for purpose. The services are available 24/7 for seven days of the week in order to reduce downtime as well as to ensure the timeous repair and delivery of the much required components to our clientele. We do not compromise on quality and we boast of superior, consistent and quality workmanship.

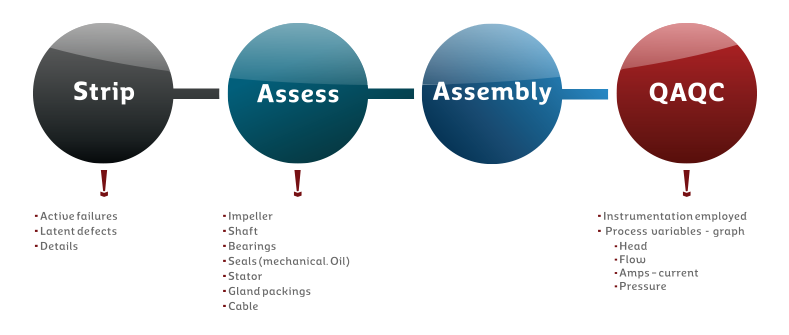

Pumps

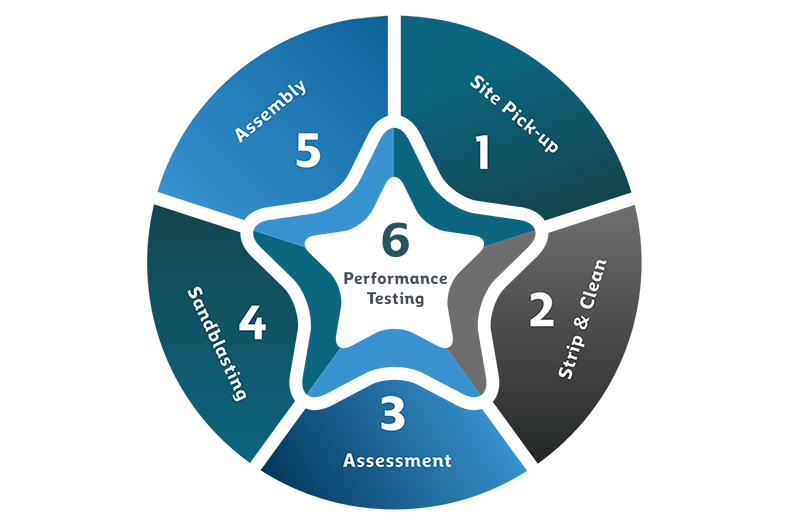

Rowani is equipped to render overhauling services on centrifugal and subsermisble pumps from various sectors. The process flow includes:

Strip, clean and assess to detect the active and latent defects

Assembly of components

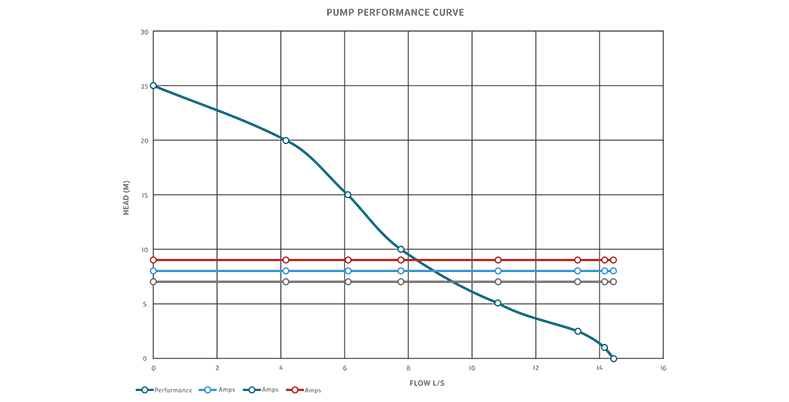

In-house quality assurance performance testing via/in the water reservoir facility to obtain process variables on the pump performance curve that are then plotted on a graph.

Electrical motors

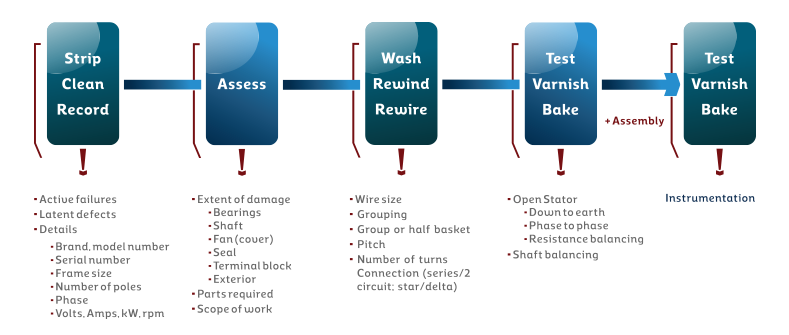

The workshop undertakes the refurbishments of AC medium and low voltage electrical motors. The process flow includes:

Strip, clean and assess to expose the known and concealed defects

Stator wash, stator coil rewind and rewiring

Varnish, test and bake

Components assembly

Performance testing on our in-house electrical motor test bay

Industrial instrumentation is applied through means of employing devices and/or sensors to assist in the measuring, recording and depiction of a number of process variables when undertaking the quality assurance performance testing of the refurbished components. The facility is equipped to measure, record and depict the following parameters:

Speed

Current, Voltage

Pressure, temperature, humidity

Levels, flow, head

Insulation Resistance

Frequency

Instrumentation for control systems and electrical projects

The company undertakes projects in the instrumentation field where various measuring instruments may be used to quantify/measure, display and record various physical parameters. This is facilitated through the installation of various instruments and sensors that are installed to meet the requirements of our customers.

The company also builds a programmable logic controller (PLC) panels and electrical panels for industrial process automation purposes. Furthermore, electrical terminal boxes are also built in-house.

These complex projects are manned by Instrumentation technicians/Control Process Engineers coupled with experienced and qualified Electricians. The company may also issue the COC upon electrical projects.

Welding/Steelworks

Rowani Engineering offers welding/steelworks/fabrication services for our clientele. We offer customized services that are designed to be fit for purpose according to the consumer specifications. To man these, we have a qualified, competent and experienced team to ensure superior quality of the end-products.

Raw steel sheets are used to fabricate various components/parts that are much needed within the working environments of our clientele.

For the mining houses, we also fabricate a range of products, e.g.:

Skids, pins, hooks, vent doors, waiting places, etc.

ELECTRICAL MOTOR (AC) LOW & MED VOLTAGE

Workshop Facility Equipped

Low:0-110-220V

Medium: 380-525V (6000V- coil)*

PUMPS - CENTRIFUGAL AND SUBMERSIBLE (DOMESTIC/INDUSTRIAL)

PROCESS FLOW TEST BAY

QUALITY ASSURANCE/PERFORMANCE TESTING

PROCESSES

Strip and assess

Stator wash, test, bake

Assemble parts

Sandblasting

Motor rewind

Test bay